iAssure™ The right code, time after time

TTO seen differently

checker reduces waste and rework with no additional

hardware, installation or training

Reduce waste & rework with iAssure™ built-in code quality checker

How iAssure™ works

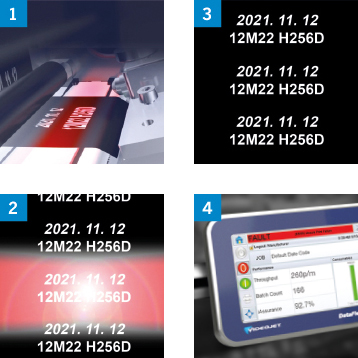

iAssure™ technology continually checks for print defects by taking a picture of every single code, assessing the quality, and if chosen limits are exceeded, rejecting the code or stopping the line. iAssure™ technology is exclusively built into the Dataflex® 6530 53mm and the 6330.

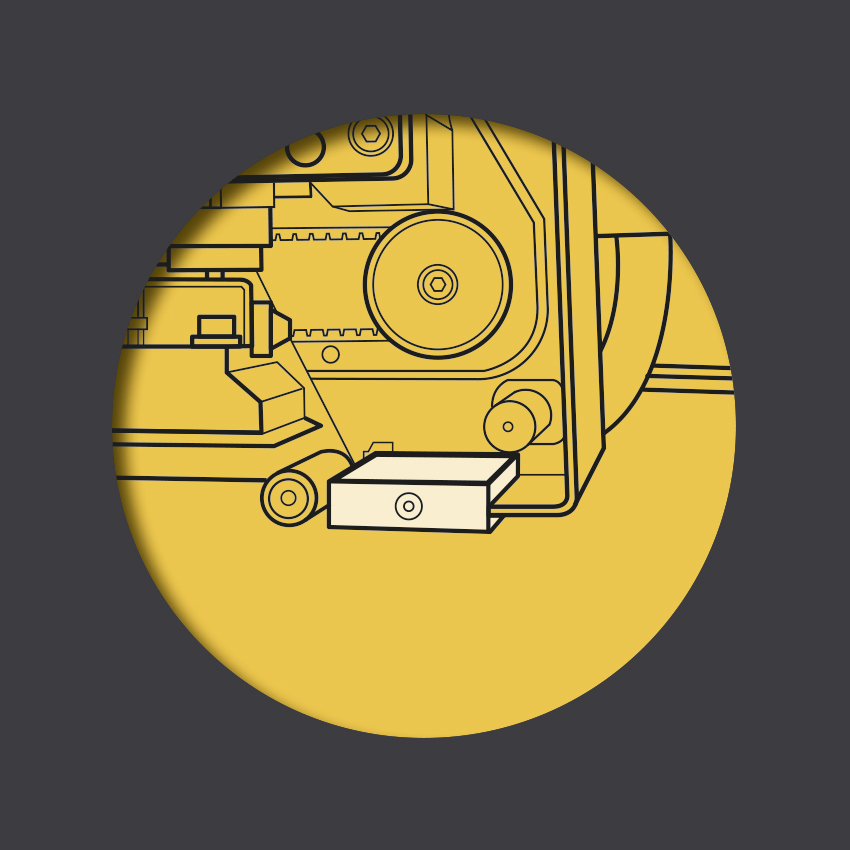

How it works

- Image capture – Built-in sensors create a perfect image of the printed TTO ribbon as it indexes to the next print.

- Image analysis – Each image is processed in real-time and assessed for quality and presence.

- Image comparison – The code quality and presence is evaluated with a pass/fail decision.

- Fault trigger event – If a pre-set number of codes fail, the printer triggers a fault that stops the line or sends product into a reject or inspection area.

*Nominal gap between successive prints is 0.02” (0.5mm). iAssure™ complements existing quality control processes. It is not designed to detect all printing errors and does not read barcodes.

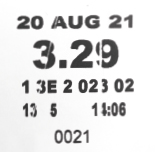

Code quality assurance

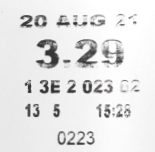

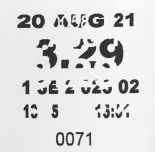

With Videojet iAssure™ technology, alphanumeric code defects like these are automatically identified when the codes are checked for legibility.

Ribbon crease due to damaged cassette

Worn print surface degrades quality

Overprint from

pre-run ribbon