Full Line of Thermal Transfer Coders for Printing and Labelling Applications

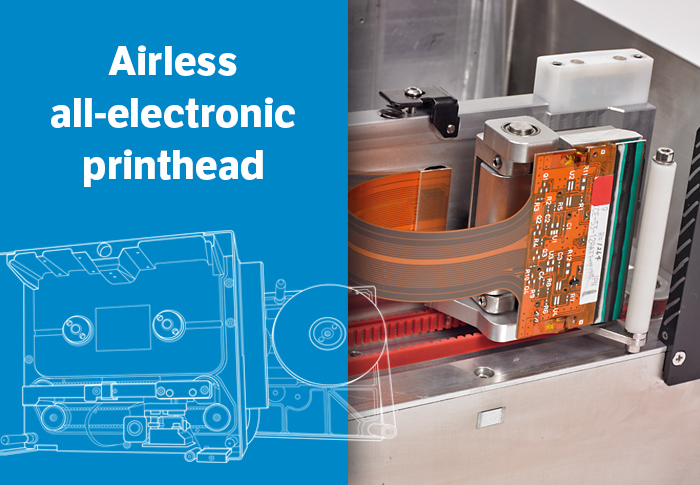

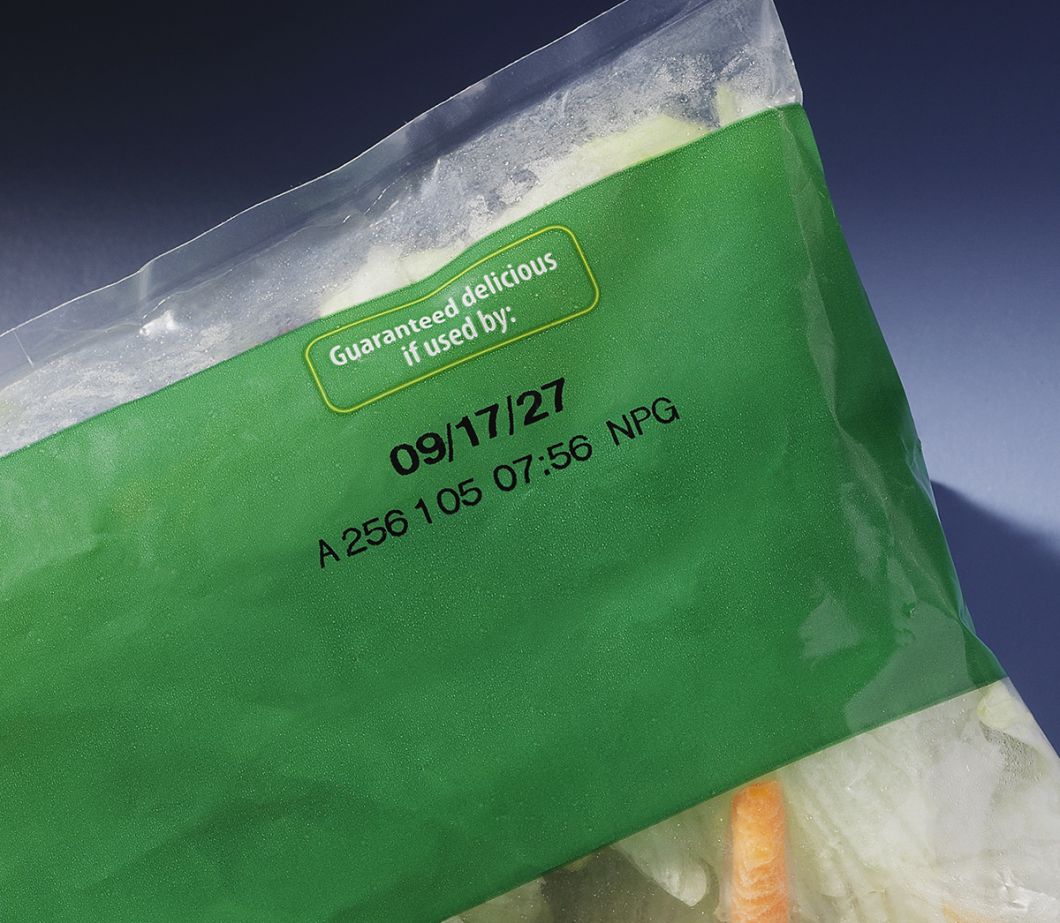

The Videojet DataFlex® line of Thermal Transfer Overprinters (TTO) delivers maximum uptime advantage and high-resolution, variable content for flexible packaging and labels. Videojet TTO printers are highly effective printing solutions widely utilised across various industries for printing variable date and batch code information on packaging materials.

Applications of Thermal Transfer Coders

Vertical flow wrapping machine integration:

- Potato Crisps

- Nuts/Seeds

- Salt and Sugar

Horizontal flow wrapping machine (Flowrapper) integration

- Baked Goods

- Confectionary

Bag filling machine integration

- Tea/Coffee

- Fruit Juice Packs

- Soups

Tray sealing integration

- Cheese

- Meat Products

Intermittent and Continuous Modes of TTO Printer

Intermittent thermal transfer printing

Continuous thermal transfer printing

Intermittent Mode

Intermittent printing is used on machines where the tape transport is stop-and-go. The stop time (dwell) of the cycle is used for printing. Using a signal from the packaging machine, the real-time printing information is prepared, the print head lowers and moves over the area to be printed. When printing is complete, the film is released and the print head returns to the start position.

Continuous Mode

This is used on continuous flow machines. The packaging material is printed while the film is moving. After a signal from the packaging machine (e.g. a visible marking), the print head is pressed against the plate roller integrated into the holding frame and the printing process starts. After printing is complete, the print head returns to the start position. The print speed is automatically adjusted to produce a consistently clear print image.

FAQ

If you’re a production manager, engineering manager, factory manager, or maintenance manager in need of a reliable, efficient solution for printing variable information on a variety of packaging materials, TTOs are your solution. These machines utilise a heat transfer process to produce high-quality, durable prints, ensuring clear and legible codes on your products.

• iAssure Technology – Its a built-in code quality checker that checks its own print

• Easy Integration- Our TTO printers can integrate into your production line with custom made brackets and minimal footprint

• 1200m Ribbon Lengths with 53mm or 107mm head widths

Selecting the thermal transfer coder for your needs can be a daunting task. To simplify the process, we recommend considering factors such as printing volume, substrate compatibility, and required print quality. Our knowledgeable team at Videojet is always ready to assist you in choosing the perfect printer that aligns with your specific requirements.

Call us directly on +44 1480 443205 to speak to an expert today!

Request a Free Quote

For Equipment Sales enquiries call us on:

Or send us your information to contact you:

Join Thousands of Industry Professionals!

Subscribe to our newsletter and stay up-to-date with the latest news, trends, and innovations in the Coding and Marking industry.