What is Plastic Bottle Coding?

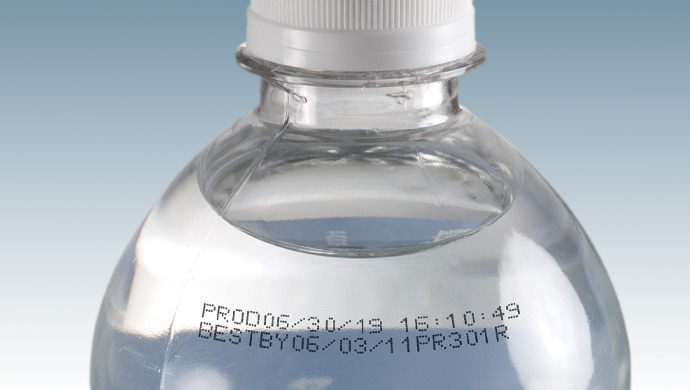

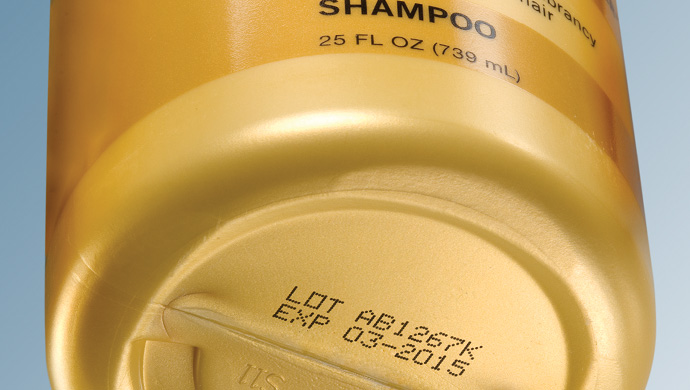

Plastic bottle coding plays a vital role in various industries, enhancing product identification and tracking. Plastic bottle coding involves imprinting crucial details onto bottles for identification. This could include batch numbers, expiration dates, barcodes, logos, and other pertinent information. Coding enables manufacturers to optimise production processes, enhance stock management, and bolster product traceability.

The importance of efficient plastic bottle coding is undeniable. It ensures compliance with industry regulations and standards, assuring product safety and quality control. It also supports product tracking and tracing throughout the supply chain, reducing the risk of counterfeiting or tampering. Furthermore, accurate coding promotes efficient stock management, reduces product recalls, and improves customer satisfaction.

Polyethylene terephthalate (PET) has long been used as a liquid container in the carbonated soft drink, bottled water, energy and fruit drinks markets due to its inherent properties of strength, flexibility and transparency. Additionally, PET bottles are gaining popularity over materials like HDPE for packaging consumer products such as shampoo.

Plastic Bottle Printing and Marking Solutions

Videojet’s application expertise in PET marking and printing on plastic bottles spans many years, including in-depth knowledge of trends such as light weighting. PET bottles are most commonly marked using continuous inkjet (CIJ) and laser printing solutions. Videojet offers a number of unique ink formulations that provide quality inkjet codes on PET and laser systems for high resolution, permanent marks.

Request a Free Quote

For Equipment Sales enquiries call us on:

Or send us your information to contact you:

Join Thousands of Industry Professionals!

Subscribe to our newsletter and stay up-to-date with the latest news, trends, and innovations in the Coding and Marking industry.

Choose the Right Equipment for Printing on Plastic Bottles

Selecting the right plastic bottle printing machine is a vital step towards achieving accurate and reliable plastic bottle coding. Several factors need consideration when making this choice.

Initially, assess the unique requirements of your coding application. The size and shape of your plastic (PET) bottles, the type of information to be coded, and even the speed of your production line should influence your choice. Equipment options like high-speed Videojet 3350 CO2 Laser and Videojet 1880 UHS (high speed inkjet printer) offer diverse capabilities to match these varying needs.

Inkjet Printing on Plastic Bottles

Continuous inkjet printers, a prevalent technology, offers versatility and high-speed coding capabilities. It can print alphanumeric codes, barcodes, and logos. However, it may not be suitable for all plastic materials due to potential adhesion issues.

Ease of maintenance and robustness are key factors to weigh when investing in coding equipment. Opt for solutions that offer simple cleaning routines and low-maintenance demands to avoid operational interruptions and maintain consistent output. What’s more, the equipment must be resilient, built to survive the daily demands of your production environment, ensuring that it remains a reliable asset for years to come.

There are various types of inks, each with unique properties. Solvent-based inks are commonly used due to their excellent adhesion and quick-drying capabilities. They penetrate the surface of the plastic bottle, creating a permanent mark resistant to smudging and wear.

UV-curable ink is another popular choice. It dries instantly when exposed to UV light, ensuring quick and efficient coding. UV-curable inks are highly resistant to fading, making them suitable for applications requiring long-term durability.

Ensuring proper ink adhesion is crucial for code legibility and durability. Our inks are formulated to adhere to various plastic materials used in bottle manufacturing, including PET, HDPE, and PVC.

Laser Printing on Plastic Bottles

Laser marking systems are another widely used technology, delivering permanent and high-quality codes, making it ideal for traceability. High-speed lasers offer exceptional precision and speed, making them an ideal choice for printing on plastic bottles. They provide high readability codes, even on curved or irregularly shaped bottles, and their permanent coding solutions resist smudging or fading, ensuring longevity.

Choose Videojet for your plastic bottle coding needs and benefit from our expertise, advanced technologies, and proven track record in providing reliable and efficient coding solutions. Call us now on +44 1480 443205.

- Suggested Plastic Printing Solutions

- Additional Resources