What is Glass Bottle Coding?

Understanding the importance of effective coding on glass bottles is crucial for product integrity, traceability, and regulatory compliance. Coding on glass bottles serves multiple purposes, from product traceability to consumer safety assurance.

It allows manufacturers to track their products throughout the supply chain, a crucial requirement in beverage industry where stringent regulations and quality control measures are in place. In bottling, efficient glass bottle coding is vital for traceability. Continuous inkjet printers excel here, offering speed, versatility, and non-contact printing. They handle high volumes while ensuring precise variable data application, making them a top choice for bottling companies.

Glass Bottle Coding and Glass Marking solutions

At Videojet, we recognise the importance of reliable and efficient glass bottle printing. Our glass bottle printers These printers enable you to mark alphanumeric batch codes, barcodes, best before dates, logos and other information onto glass packaging.

Choosing the Right Equipment for Glass Printing

Selecting the right bottle printing machine is a vital step towards achieving accurate and reliable glass bottle coding. Several factors need consideration when making this choice.

Initially, assess the unique requirements of your coding application. The size and shape of your glass bottles, the type of information to be coded, and even the speed of your production line should influence your choice. Equipment options like high-speed lasers and inkjet printers offer diverse capabilities to match these varying needs.

Inkjet Printing on Glass Bottles

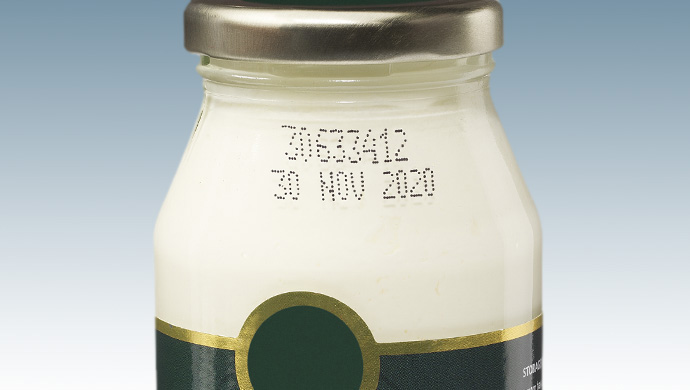

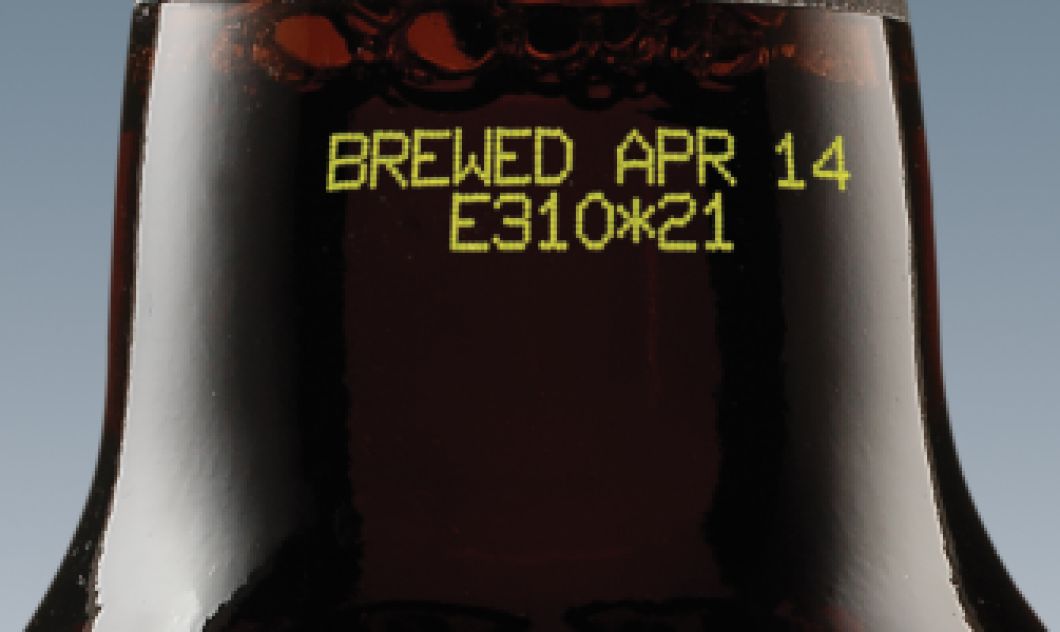

Inkjet printers bring versatility and flexibility to printing on glass bottles. They can handle a variety of coding requirements, from alphanumeric codes to barcodes, logos, and expiration dates, and are also capable of high-speed production lines.

Maintenance and durability of the coding equipment are also crucial considerations. Equipment that is easy to clean and maintain will minimise downtime and ensure consistent performance. Moreover, equipment must be robust enough to withstand the demands of your production environment.

Videojet inkjet glass bottle printers feature pigmented inks for printing high-contrast codes onto dark glass or clear glass bottles containing dark liquids. A unique ink formulation enables the printing of high quality inkjet codes, which can also be easily removed for returnable bottle applications. Videojet also offers an ink solution that changes colour to validate the autoclave process for glass bottles being sterilised.

Laser Printing on Glass Bottles

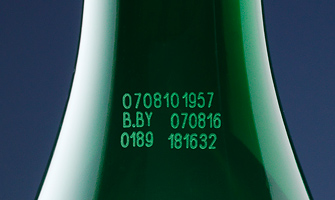

High-speed lasers offer exceptional precision and speed, making them an ideal choice for glass bottle coding. They provide high readability codes, even on curved or irregularly shaped bottles, and their permanent coding solutions resist smudging or fading, ensuring longevity.

Videojet’s laser marking systems can print high-resolution permanent codes on virtually any type or colour of soda lime silica glass container (the most common glass in the industry).

Glass bottles and containers remain a popular packaging option for a number of reasons – including product differentiation and identification of a premium product. In addition, its re-use (returnable bottles) and recyclability make it an environmentally conscious choice. Glass bottles are popular for a variety of food and beverage products and those that require a strong barrier protection.

Likewise, the commercial glazing products market continues to grow, where glass manufacturers and processors are required under the British Standard Code of Practice BS6262-4 to include visible identifying marks and safety marks (such as CE marks, Kitemark symbols) on panes.

Request a Free Quote

For Equipment Sales enquiries call us on:

Or send us your information to contact you:

Join Thousands of Industry Professionals!

Subscribe to our newsletter and stay up-to-date with the latest news, trends, and innovations in the Coding and Marking industry.

- Suggested Solutions for Glass Printing

- Additional Resources

Videojet 1880HR Glass Inkjet Printer

High resolution inkjet printer ideal for simple marking at high speeds typical of bottling lines.

Up to three lines of print and complex 2D codes, ideal for applications where legibility is critical and print space is limited.

The inkjet printer can print on bottles of beer or wine.

Videojet 3350 Laser Marker for Glass

Increase your productivity with the Videojet 3350 laser. Ideal for high-quality glass marking, it is able to print traceability codes and QR/Datamatrix codes at high speeds. The Videojet laser range enables accurate and permanent glass etching or engraving on any type of glass in industrial sectors such as beverage, aerospace and automotive.

Success Stories in Glass Bottle Coding

Videojet has successfully implemented coding solutions for glass bottle coding in a range of industries. Our case studies demonstrate the effectiveness of our solutions in improving efficiency and productivity.

- A leading beverage manufacturer sought our expertise to code large volumes of glass bottles with variable information, such as batch numbers, expiration dates, and barcodes. We integrated our advanced laser marking technology into their production line, enabling high-speed, permanent, and legible coding on glass surfaces, ensuring traceability and compliance.

Testimonial

“From an operator’s point of view, the Videojet lasers are far easier to work with. There is no real need for maintenance.” – Barry Murray, Operator

- In another instance, a pharmaceutical company required coding on delicate glass vials. Our inkjet technology provided the ideal solution. It delivered high-resolution codes that adhered well to the glass surface, ensuring readability throughout the product lifecycle.

Our clients have seen remarkable improvements in efficiency by automating the coding process and eliminating manual errors. They have experienced improved production line speeds, reduced downtime, and enhanced overall quality control. With Videojet solutions, businesses can efficiently meet regulatory requirements, track products in the supply chain, and ensure customer satisfaction.

Choose Videojet for your glass bottle coding needs and benefit from our expertise, advanced technologies, and proven track record in providing reliable and efficient coding solutions. Call us now on +44 1480 443205.