Industrial labelling machines are used in various different manufacturing contexts, typically on production lines, to apply labels to individual products, cases and pallets. Common labelling machine types include print and apply labellers and automatic label applicators for pre-printed labels.

The demand for industrial labelling machines varies widely among different sectors. Virtually all companies that make and sell products need to label them – for their own inventory control needs, to meet regulatory rules and to help consumers choose the correct product for their needs. But company size, the size of its markets and the extent of its distribution methods all have an effect on its labelling requirements.

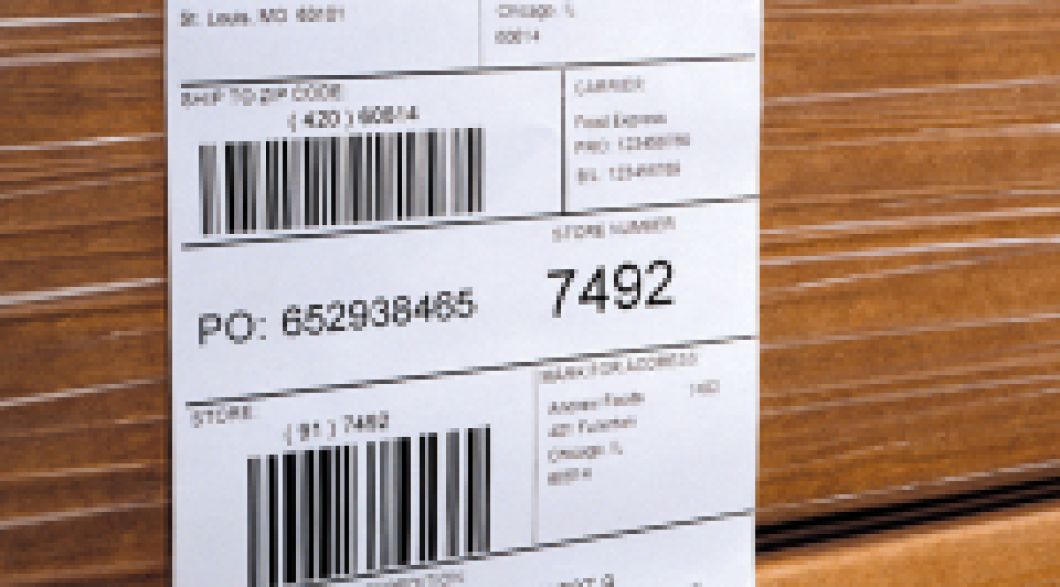

Small manufacturers can usually use hand-applied labels successfully. These may be pre-printed labels or labels created by a simple print-and-apply system. A mid-sized company may require an automated labeller to match the higher speed of its production output. But the greatest labelling challenges arise when a company becomes very large, and ships a multitude of products to a wide, even global, marketplace. Such companies require industrial labelling machinery to meet their extensive labelling needs. These are highly reliable automated label applicators running at high speeds.

Advantages of Industrial Labelling Machines

In recent years, while the technology of traditional print-and-apply label systems has remained essentially unchanged, automatic label print-and-apply machines have undergone extensive evolutionary changes. Design changes have reduced or even eliminated the need for operators to make mechanical adjustments, and wear parts and failure points that slowed production in the past have been removed. Machine control is more precise and the need for a label applicator has been removed from the labelling system.

Today’s electronically controlled industrial labelling systems can print optimum quality case labels and apply them precisely on up to 150 cases per minute, hour after hour. And the process, from selection of the label content to placement of a label after assembling it and visually approving it on the label machine’s HMI screen, is digital, not mechanical.

As a result, today’s industrial automatic label machines deliver highly reliable performance and high speed application, combined with maintenance-free productivity.

Suggested Industrial Labelling Solutions

Categories

Contact Us

For Sales Enquiries please call us free on: +44 1480 443205

For the main switchboard please call:

+44 (1480) 443160

Press 1 for Equipment Sales

Press 2 for Service, Support, Parts & Consumables

For other departments please use the auto attendant

Join Thousands of Industry Professionals!

Subscribe to our newsletter and stay up-to-date with the latest news, trends, and innovations in the Coding and Marking industry.